welcome to cassinian software

Cassinian Software is a developer of image processing, printer calibration, and color management software tools for digital printing. Our software libraries, which we license to printer manufacturers, OEMs, and value-added resellers, are used to convert digital images to formats suitable for printing. They include functions for error diffusion halftoning, color matching, file management and network print spooling, calibration and process control.

With our software libraries and consulting support, printer manufacturers, VARs and OEMs can work quickly to design their own custom end-user software and print drivers, keeping focused on their user interface and user experience. The complex operations of halftoning, calibration, and color management are handled via our custom APIs. Cassinian can provide as much (or as little) development support as necessary; we have extensive experience working with remote engineering teams and contract developers. And, included with each library is C source code to demonstrate calls to the external functions that form the API.

With our software libraries and consulting support, printer manufacturers, VARs and OEMs can work quickly to design their own custom end-user software and print drivers, keeping focused on their user interface and user experience. The complex operations of halftoning, calibration, and color management are handled via our custom APIs. Cassinian can provide as much (or as little) development support as necessary; we have extensive experience working with remote engineering teams and contract developers. And, included with each library is C source code to demonstrate calls to the external functions that form the API.

|

Appaloosa™ is our digital halftoning library created specifically for variable-dot inkjet color printers. It employs Dynamic Frequency Response, a.k.a. DFR Screening™, our method of error diffusion halftoning that works to minimize printer-induced artifacts, such as horizontal banding and graininess, caused by inaccurate dot placement which tend to be more obvious in lower frequency areas of an image. It achieves this by dynamically tuning variable dot use in real-time, and by adaptively injecting higher frequency stochastic patterns to break up low frequency patterns that would otherwise be more visually objectionable.

Our goal is to reproduce images on your chosen substrate that look as good as what you see on your monitor, without compromising color reproduction accuracy or dynamic range. Our proprietary halftoning solutions were developed internally, from scratch, with no reliance on proprietary third-party libraries. And, we do all of our own development in-house, to protect the IP of our clients. |

MORE CPUs, MORE SPEED

Appaloosa was developed as a cross-platform error diffusion library that combines calibration, halftoning, and ICC-compatible color matching to create a complete digital print workflow as an API. It leverages support for modern multi-core processors and common GPU devices to accelerate image processing, providing high-performance even on inexpensive, low-end hardware. Appaloosa has been optimized for variable dot drop-on-demand inkjet printing, and can support up to 4-bit dots (16 dot levels per channel), light density inks, and secondary process colors.

BETTER SOFTWARE, BETTER IMAGES

We do all of our own development in-house, to protect the IP of our clients; and, we can adapt our technology to a wide range of printing systems and hardware platforms. We license our software typically with a simple up-front non-exclusive, royalty-free license agreement, and provide ongoing support and updates through annually recurring maintenance contracts. We also offer engineering development and consulting retainer services, NRE agreements, and on-demand software engineering with negotiable hourly rates. If you are a printer manufacturer, OEM, VAR, or system integrator looking to embed digital halftoning, calibration, and color matching into your platform, to take complete control of your image processing workflow, contact us today. We would be happy to review your project requirements and suggest how our technology could be integrated into your hardware solution.

WE DO NOT SELL END-USER SOFTWARE

Cassinian Software works only with manufacturers, OEMs, and VARs to integrate our technology into your hardware solution. While we also work with system integrators and corporate users with specialized requirements, we do not sell end-user software, nor do we provide desktop-style applications. We license our technology as binary software libraries, where they function "under the hood" with no visible branding to the end-user. Your solution remains 100% unique to you and your brand; we simply help fill the gaps in your back-end image processing workflow, allowing you to focus on the big picture – your solution, your application, and your customers.

LESS RISK, LOWER COST, FASTER TIME TO MARKET

Our team has over 30 years’ experience developing software tools for digital imaging, from calibration tools, print drivers, RIP software and hardware, to color sensors, process control, and profiling utilities. The technology we have today is the culmination of that experience, which means less development risk for you, and a faster time to market. In most cases, we can get a new client up and running with evaluation software in a matter of days, regardless of where you are in the world. And, our licensing fees are typically a fraction of the cost of a single full-time developer (with comparable experience). Why reinvent the wheel, when the work is already done?

THE PROOF IS THE PUDDING

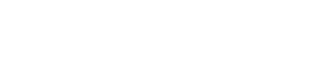

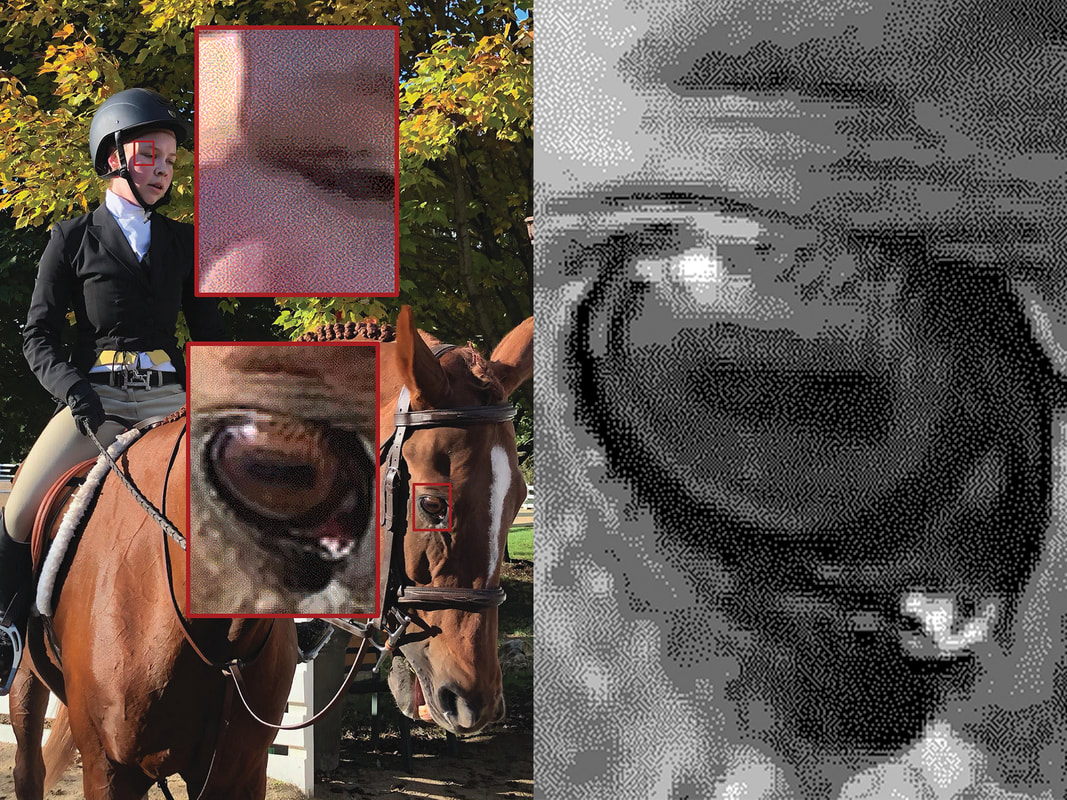

An old English idiom says, “the proof of the pudding is in the eating,” and we agree, although in our case the proof is in the seeing. Below are links to four downloadable files, two sets of two, that you can view with your favorite TIFF image viewer. Both sets are CMYK, one in color and one K-only. One of each set is the original 200 dpi photographic image (the 64-bit continuous tone original), and the other is the 2-bit halftoned image at 600 dpi. In the case of the halftoned images, each pixel represents one dot of either 33% (small dot), 67% (medium dot) or 100% (large dot) density. This simulates the printed page.

These images allow you to study the halftone pattern in detail, to see how it recreates the continuous tone original using just three dot densities (dot sizes). And, of course, these are mere samples; our digital halftoning library supports many different options, including multiple error diffusion kernels, hysteresis settings, scanline settings, and numerous printer-specific settings to optimize image quality to your unique hardware. Feel free to download and study.

Once you are ready to contact us for a more in-depth discussion, we can put an NDA in place and then prepare evaluation software that you can use to print directly to your equipment. In many cases, we can get evaluation software prepared in less than a week, once we have technical details relating to your print data format and printer configuration.

Grayscale Sample @ 600 dpi + Original (15MB)

Color Sample @ 600 dpi + Original (37MB)

An old English idiom says, “the proof of the pudding is in the eating,” and we agree, although in our case the proof is in the seeing. Below are links to four downloadable files, two sets of two, that you can view with your favorite TIFF image viewer. Both sets are CMYK, one in color and one K-only. One of each set is the original 200 dpi photographic image (the 64-bit continuous tone original), and the other is the 2-bit halftoned image at 600 dpi. In the case of the halftoned images, each pixel represents one dot of either 33% (small dot), 67% (medium dot) or 100% (large dot) density. This simulates the printed page.

These images allow you to study the halftone pattern in detail, to see how it recreates the continuous tone original using just three dot densities (dot sizes). And, of course, these are mere samples; our digital halftoning library supports many different options, including multiple error diffusion kernels, hysteresis settings, scanline settings, and numerous printer-specific settings to optimize image quality to your unique hardware. Feel free to download and study.

Once you are ready to contact us for a more in-depth discussion, we can put an NDA in place and then prepare evaluation software that you can use to print directly to your equipment. In many cases, we can get evaluation software prepared in less than a week, once we have technical details relating to your print data format and printer configuration.

Grayscale Sample @ 600 dpi + Original (15MB)

Color Sample @ 600 dpi + Original (37MB)

Printer Calibration & PROCESS CONTROL

Printer Calibration is where Cassinian began in June 2016, developing tools to automate inkjet printer calibration, color management and process control for digital print. Proper printer calibration is critical to high-quality image reproduction, but very often halftoning and calibration are treated as separate components. Rather than optimizing the halftone algorithm to account for the idiosyncrasies of the printer, traditional algorithms rely on static settings that get pushed to the other side of the hardware/software divide. This forces the calibration process, comprised primarily of ink limits and linearization curves, to compress the color gamut and dynamic range of the input image to "fit" the limitations of the printer. But only through halftone optimization can you maximize the gamut and dynamic range of the printer.

If the uncalibrated printer lays down too much ink, produces mottled shadows, and fails to print linear tone gradients, the fault lies not so much with the printer, but with the halftoning algorithm itself. Hardware will always be limited to some extent by physics, but software has no such limitation. By considering the physical attributes of the printer, ink, and media, such as drop volumes, ink film thickness, media dot gain, maximum media ink load, light scattering effects, and relative ink densities, our Appaloosa™ halftoning library can be optimized to eliminate much of the work of the calibration function, leading to better and more consistent results.

Halftone optimization, especially when combined with variable dot hardware, can virtually eliminate the need for the setting of ink limits and linearization curves, taming even the unruliest of printers before applying calibration. This is one of the key attributes of our DFR Screening – not only does it improve overall image quality, but it also simplifies calibration and color matching, yielding greater consistency and better process control for a better overall customer experience.

To learn more about our calibration technologies, and how they may benefit your company, click here.

If the uncalibrated printer lays down too much ink, produces mottled shadows, and fails to print linear tone gradients, the fault lies not so much with the printer, but with the halftoning algorithm itself. Hardware will always be limited to some extent by physics, but software has no such limitation. By considering the physical attributes of the printer, ink, and media, such as drop volumes, ink film thickness, media dot gain, maximum media ink load, light scattering effects, and relative ink densities, our Appaloosa™ halftoning library can be optimized to eliminate much of the work of the calibration function, leading to better and more consistent results.

Halftone optimization, especially when combined with variable dot hardware, can virtually eliminate the need for the setting of ink limits and linearization curves, taming even the unruliest of printers before applying calibration. This is one of the key attributes of our DFR Screening – not only does it improve overall image quality, but it also simplifies calibration and color matching, yielding greater consistency and better process control for a better overall customer experience.

To learn more about our calibration technologies, and how they may benefit your company, click here.